Laini Iṣelọpọ Obe Custard

Laini Iṣelọpọ Obe Custard

Laini Iṣelọpọ Obe Custard

Fídíò Ìṣelọ́pọ́:https://www.youtube.com/watch?v=AkAcycJx0pI

Alaini iṣelọpọ obe custardÓ ní nínú àwọn ìlànà aládàáṣe àti aládàáṣe díẹ̀ láti ṣe obe custard lọ́nà tó dára, déédé, àti ní ìmọ́tótó. Ní ìsàlẹ̀ yìí ni àlàyé kíkún nípa àwọn ìpele tí ó wọ́pọ̀ nínú ìlà iṣẹ́ ṣíṣe obe custard:

1. Ìmúlò àti Ìmúrasílẹ̀ Àwọn Èròjà

- Gbigba wara ati ibi ipamọ

- A gba wara aise, a dán an wò fun didara rẹ̀, a sì tọ́jú rẹ̀ sínú àwọn silos tí a fi fìríìjì pamọ́.

- Àfikún: Ìyẹ̀fun wàrà tí a tún ṣe + omi (fún ìgbà pípẹ́).

- Ìtọ́jú Súgà àti Ohun Adùn

- A máa ń wọn sùgà, omi àgbàdo, tàbí àwọn ohun dídùn mìíràn tí a ó fi yọ́.

- Ṣíṣe ìtọ́jú lulú ẹyin àti ẹyin

- A fi omi da ẹyin olomi (ti a ti fi pasteurized) tabi ẹyin lulú.

- Àwọn ohun èlò ìdúróṣinṣin àti àwọn ohun èlò ìdúróṣinṣin

- A máa ń da ọkà, sitashi tí a ti yípadà, tàbí àwọn ohun tí ó nípọn (fún àpẹẹrẹ, carrageenan) pọ̀ tẹ́lẹ̀ láti dènà kí ó má baà dìpọ̀.

- Àwọn adùn àti àwọn àfikún

- A máa ń ṣe Fanila, caramel, tàbí àwọn adùn mìíràn, pẹ̀lú àwọn ohun ìpamọ́ (tí ó bá pọndandan).

2. Ṣíṣe àdàpọ̀ àti Ṣíṣe àdàpọ̀

- Batch tàbí Continuous Adalu

- A da awọn eroja pọ niẹ̀rọ amúlétutù gígatabiojò àfikúnlábẹ́ àwọn iwọ̀n otutu tí a ṣàkóso (láti yẹra fún kíkùn tí kò tó àkókò).

- A le lo Isọdọtun fun isọdi ti o dan.

3. Sísè àti Ṣíṣe Pasteurization

- Sísè Títẹ̀síwájú (Pípàṣípààrọ̀ Ooru Ilẹ̀ Tí A Gbẹ́)

- A fi ooru mu adalu naa si75–85°C (167–185°F)láti mú kí sítáṣì gelatinization ṣiṣẹ́ kí ó sì le koko.

- Pasteurization (HTST tabi Batch)

- Akoko kukuru ti o gbona giga (HTST) ni72°C (161°F) fún ìṣẹ́jú-àáyá 15-20tàbí ìṣàtúnṣe ìpele láti rí i dájú pé àwọn kòkòrò àrùn wà.

- Ipele Itutu

- Itutu tutu ni kiakia si4–10°C (39–50°F)láti dáwọ́ sísè síwájú sí i dúró kí o sì máa tọ́jú ìrísí ara.

4. Ṣíṣe àdàpọ̀ (Àṣàyàn)

- Homogenizer titẹ giga

- A lo fun apẹrẹ ti o dan pupọ (o ṣe idiwọ jijẹ eso).

5. Kíkún àti Àkójọpọ̀

- Awọn Ẹrọ Ikun Aifọwọyi

- Kíkún àpò(fún títà ọjà) tàbíìkún púpọ̀(fún iṣẹ́ oúnjẹ).

- Ìkún Àìseptíkì(fún ìgbà pípẹ́) tàbíkikun-gbona(fun ibi ipamọ ayika).

- Àwọn Fọ́ọ̀mù Àkójọ:

- Àwọn ìgò ṣíṣu, àwọn páálí, àwọn àpò, tàbí àwọn agolo.

- A le lo fifa nitrogen lati fa igbesi aye selifu gun.

6. Itutu ati Ibi ipamọ

- Bọ́ǹbù Ìtútù (tí ó bá jẹ́ dandan)

- Fún custard tí a fi sínú fìríìjì, kíákíá ìtútù sí4°C (39°F).

- Ibi ipamọ tutu

- Ti tọ́jú ní4°C (39°F)fún custard tuntun tàbí àyíká fún àwọn ọjà tí a fi UHT ṣe.

7. Iṣakoso Didara ati Idanwo

- Àwọn Àyẹ̀wò Ìrísí(lilo awọn viscomets).

- Abojuto pH(àfojúsùn: ~6.0–6.5).

- Idanwo Microbiological(iye gbogbo awo, iwukara/ewé).

- Ìṣàyẹ̀wò Ìmọ́lẹ̀(ìtọ́wò, ìrísí, àwọ̀).

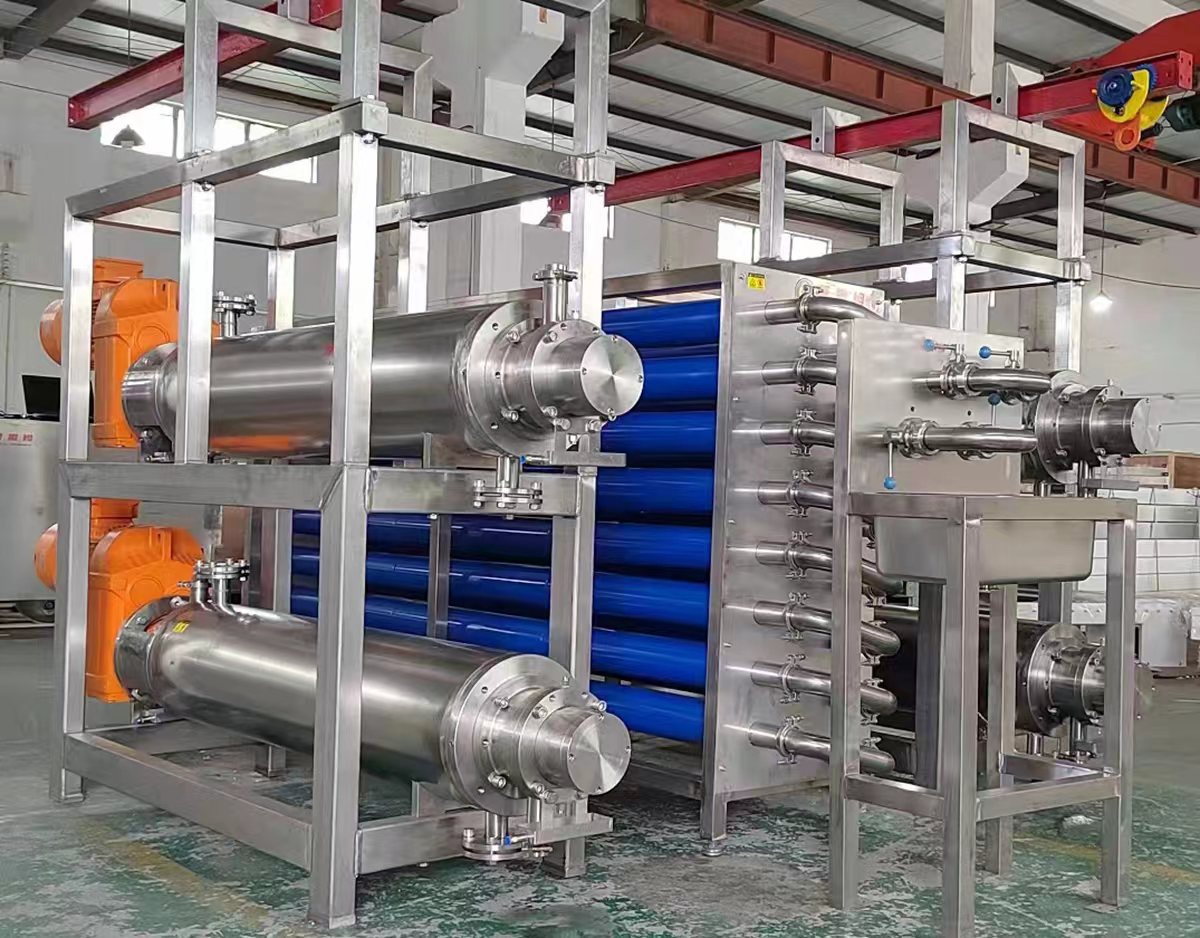

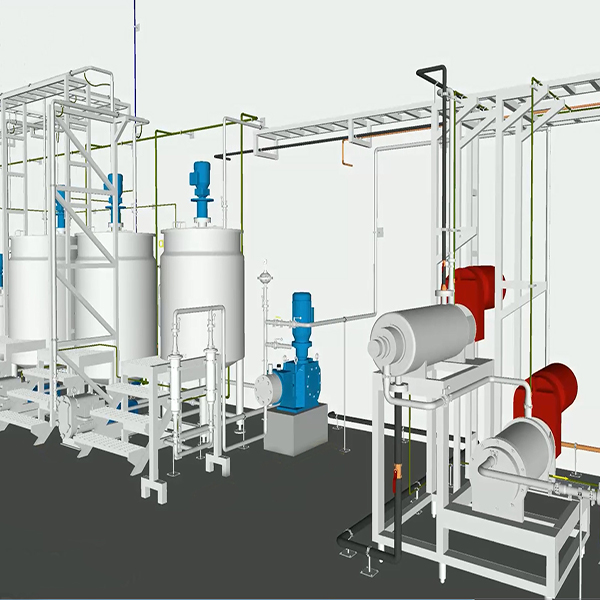

Ohun elo pataki ni laini iṣelọpọ obe custard

- Àwọn Àpò Ìpamọ́(fún wàrà, àwọn èròjà omi).

- Àwọn Ètò Ìwọ̀n àti Ìwọ̀n Lílò.

- Àwọn Ohun Èlò Ìdápọ̀ Gíga àti Àwọn Tankì Premix.

- Pasteurizer (HTST tabi Batch).

- Ẹ̀rọ Paarẹ Ooru Oju Ti A Ti Gé (fun sise).

- Homogenizer (àṣàyàn).

- Awọn Ẹrọ Fikun (piston, volumetric, tabi aseptic).

- Àwọn Ọ̀nà Ìtutù.

- Àwọn Ẹ̀rọ Ìkópamọ́ (ìdìmọ́, àmì sílébù).

Àwọn Irú Obe Kọ́sítàdì Tí A Ṣe

- Kọ́sítàdì tí a fi sínú fìríìjì(ìgbésí ayé ìpamọ́ kúkúrú, ìtọ́wò tuntun).

- UHT Custard(ìgbésí ayé ìgbà pípẹ́, tí a ti tọ́jú).

- Àdàpọ̀ Kọ́sítàdì Tí A Fi Pupa Ṣe(fún àtúntò).

Àdáṣiṣẹ́ àti Ìṣiṣẹ́

- Àwọn Ètò Ìṣàkóso PLCfun iṣakoso iwọn otutu deede ati adapọ.

- Àwọn Ètò CIP (Mímọ́-ní-Ibi)fún ìmọ́tótó.

Iṣẹ́ Ààyè

Kọ ifiranṣẹ rẹ si ibi ki o fi ranṣẹ si wa