Laini Itoju Puff Pastry Margarine

Laini Itoju Puff Pastry Margarine

Fídíò Ìṣelọ́pọ́:https://www.youtube.com/watch?v=3cSJknMaYd8

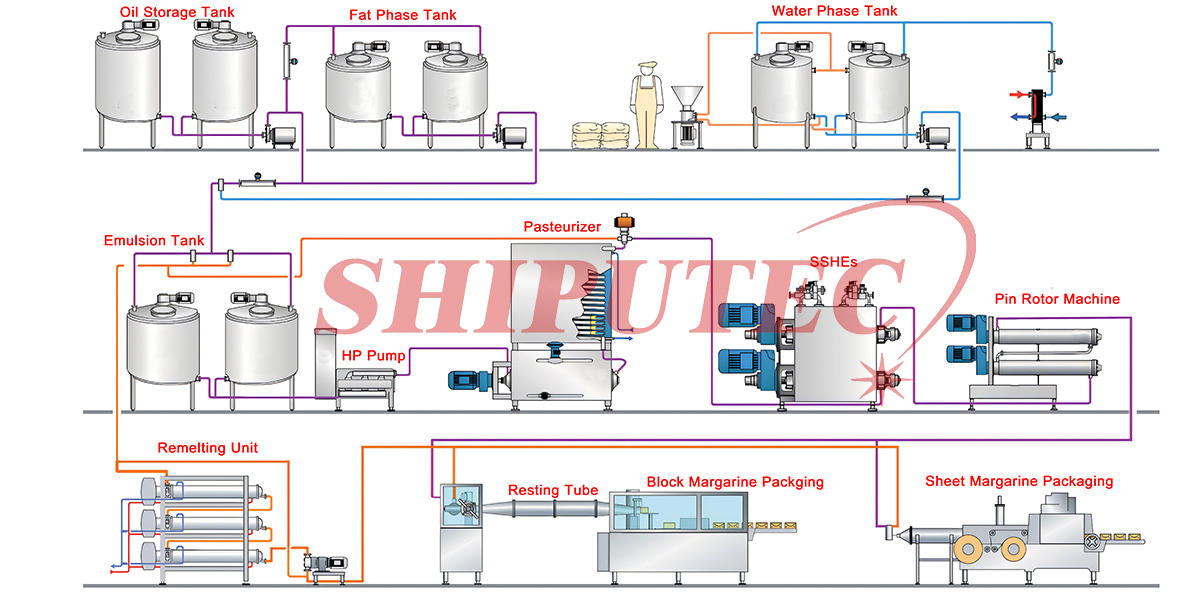

Margarine jẹ́ àrọ́pò bọ́tà tí a fi epo ewébẹ̀, ọ̀rá ẹranko tàbí àwọn orísun ọ̀rá mìíràn ṣe. Àwọn ohun èlò ìṣelọ́pọ́ àti ìṣiṣẹ́ rẹ̀ ti dàgbàsókè gidigidi lẹ́yìn ọ̀pọ̀ ọdún ìdàgbàsókè. Àwọn wọ̀nyí ni ìṣàyẹ̀wò ìlànà àti ìfìhàn àwọn ohun èlò pàtàkì:

I. Ilana Iṣelọpọ Margarin

1. Ìpèsè Ohun Èlò Aláìsí

• Àwọn ohun èlò pàtàkì:

o Àwọn epo (tó tó 80%): bíi epo ọ̀pẹ, epo soybean, epo rapeseed, epo àgbọn, àti bẹ́ẹ̀ bẹ́ẹ̀ lọ, èyí tí a nílò láti tún ṣe (dídí dí ...

o Ipele omi (nipa 15-20%): wara ti a ti yọ kuro, omi, iyọ, awọn emulsifiers (bii lecithin, mono-glyceride), awọn ohun ti n daabobo (bii potassium sorbate), awọn vitamin (bii Vitamin A, D), awọn adun, ati bẹbẹ lọ.

o Àwọn afikún: àwọ̀ (β-carotene), olùṣàkóso ìṣàn ẹ̀jẹ̀ (lactic acid), àti bẹ́ẹ̀ bẹ́ẹ̀ lọ.

2. Ṣíṣe àdàpọ̀ àti ìfọ́mọ́ra

• Ìdàpọ̀ ìpele epo àti ìpele omi:

A máa gbóná ìpele epo (àwọn afikún epo àti epo tí ó lè yọ́) sí 50-60℃, a sì máa yọ́.

A máa gbóná omi (omi + àwọn afikún omi tí ó lè yọ́) kí a sì fi sínú ìkòkò (pasteurization, 72℃/15 àáyá).

Àwọn ìpele méjèèjì ni a dapọ̀ ní ìwọ̀n, a sì fi àwọn emulsifiers (bíi mono-glyceride, soy lecithin) kún un, a sì fi emulsion kan tí ó jọra (irú omi-nínú-epo tàbí irú epo-nínú-omi) ṣẹ̀dá nípasẹ̀ ìrúpọ̀ iyàrá gíga (2000-3000 rpm).

3. Itutu ati kikopa yara (Igbese Pataki)

• Itutu tutu ni kiakia: Emulsion naa ni a tutù ni kiakia si 10-20℃ nipasẹ ẹrọ iyipada ooru ti a ti fọ (SSHE), eyiti o fa ki a ṣẹda apakan kirisita ti epo lati ṣẹda apẹrẹ kirisita β (pataki si awọ ti o dara).

• Ṣíṣe àtúnṣe: A máa ń gé ọ̀rá díẹ̀-líle nípasẹ̀ ẹ̀rọ ìfọ́mọ́ (Pin Worker) ní 2000-3000 rpm láti fọ́ àwọn kirisita ńláńlá kí ó sì ṣẹ̀dá ìṣètò ọ̀rá tí ó dára àti tí ó dọ́gba, kí ó má baà ní ìmọ̀lára kíkorò.

4. Ìdàgbàsókè àti Àkójọpọ̀

• Dídàgbà: A fi sílẹ̀ láti dúró ní 20-25℃ fún wákàtí 24-48 láti mú kí ìṣètò kristali náà dúró ṣinṣin.

• Àpò: A máa ń kún un gẹ́gẹ́ bí búlọ́ọ̀kì, agolo, tàbí irú ìfọ́nrán, a sì máa ń tọ́jú rẹ̀ sínú fìríìjì (a lè tọ́jú díẹ̀ lára mágárínì tó rọ̀ ní iwọ̀n otútù yàrá tààrà).

II. Ohun èlò ìṣiṣẹ́ mojuto

1. Ohun elo Ṣaaju-itọju

• Àwọn ohun èlò ìtúnṣe epo: centrifuge ìtújáde epo, ilé ìṣọ́ ìtújáde epo, ojò ìtújáde epo, ilé ìṣọ́ ìtújáde epo.

• Ohun èlò ìṣiṣẹ́ ìpele omi: ẹ̀rọ ìpalẹ̀mọ́, homogenizer onítẹ̀ gíga (tí a lò fún ìṣọ̀kan wàrà tàbí ìpele omi).

2. Ohun elo Emulsifikasi

• Àpò ìtújáde: àpò ìtújáde irin alagbara pẹ̀lú àwọn iṣẹ́ ìtújáde àti ìgbóná (bíi àpò ìtújáde tàbí ẹ̀rọ ìtújáde irin turbine).

• Homogenizer titẹ giga: tun ṣe atunṣe awọn droplets emulsion (titẹ 10-20 MPa).

3. Ohun elo Itutu Yara

• Ẹ̀rọ Paarẹ Ooru Oju Ti A Ti Pa (SSHE):

o Ó máa tutù kíákíá títí tí ó fi máa di yìnyín díẹ̀díẹ̀, pẹ̀lú ẹ̀rọ ìfọ́ tí ń yípo láti dènà ìfúnpọ̀.

Àwọn orúkọ ìtajà tó wọ́pọ̀: Gerstenberg & Agger (Denmark), Alfa Laval (Sweden), SPX flow (USA), Shiputec (China)

• Oníṣẹ́ Pínì:

o Gé ọ̀rá náà nípasẹ̀ ọ̀pọ̀lọpọ̀ àwọn ìdìpọ̀ láti ṣàkóso ìwọ̀n kírísítàlì náà.

4. Awọn Ẹrọ Iṣakojọpọ

• Ẹ̀rọ ìkún-ẹ̀rọ aládàáṣe: fún àwọn bulọọki (25g-500g) tàbí ìdìpọ̀ àgbá (1kg-20kg).

• Ìlà ìdìpọ̀ aláìléèérí: ó dára fún àwọn ọjà tí a lè lò fún ìgbà pípẹ́ (bíi margarine olómi tí a fi UHT tọ́jú).

III. Awọn Oniruuru Ilana

1. Margarine Rírọ̀: Ipò gíga ti epo omi ninu epo (bii epo sunflower), ko si iwulo fun imudọgba itutu ni kiakia, ti a ṣe ni apapo taara ati ti a fi sinu apo.

2. Margarine oní ọ̀rá díẹ̀: Àkóónú ọ̀rá 40-60%, ó nílò fífi àwọn ohun èlò ìfúnpọ̀ kún un (bíi gelatin, sítáṣì tí a ti yípadà).

3. Margarine tí a fi ewéko ṣe: Fọ́múlá epo gbogbo-igi, kò sí àwọn èròjà trans fatty acids (ṣatunṣe aaye yo nipasẹ paṣipaarọ ester tabi imọ-ẹrọ ìpín).

IV. Awọn Koko Pataki Iṣakoso Didara •

Ìrísí Kírísítàlì: Ìrísí kírísítàlì β' (tó ga ju ìrísí kírísítàlì β lọ) nílò ìṣàkóso ìwọ̀n pípa iná àti agbára ìdàpọ̀.

• Ààbò àwọn kòkòrò àrùn: A gbọ́dọ̀ tọ́jú ìpele omi dáadáa, kí a sì tún pH ṣe ní ìsàlẹ̀ 4.5 láti dènà bakitéríà.

• Ìdúróṣinṣin ìfàsẹ́yìn: Fi àwọn ohun tí ó ń dènà ìfàsẹ́yìn (bíi TBHQ, Vitamin E) kún un láti yẹra fún ìbàjẹ́ ion irin.

Nípasẹ̀ àpapọ̀ àwọn ìlànà àti ohun èlò tí a mẹ́nu kàn lókè yìí, ìpara olóògbé ayé lè ṣe àfarawé ìtọ́wò bọ́tà nígbà tí ó bá ń bá àwọn ohun tí a nílò fún ìlera mu bíi cholesterol díẹ̀ àti ọ̀rá tí ó ní àjẹyó díẹ̀. A gbọ́dọ̀ ṣe àtúnṣe ìlànà àti ìlànà pàtó náà gẹ́gẹ́ bí ibi tí a gbé ọjà náà sí (bíi fún yíyan tàbí fún lílo lórí àwọn ohun èlò oúnjẹ).

Iṣẹ́ Ààyè